Highly Selective Separations: SuperLig®

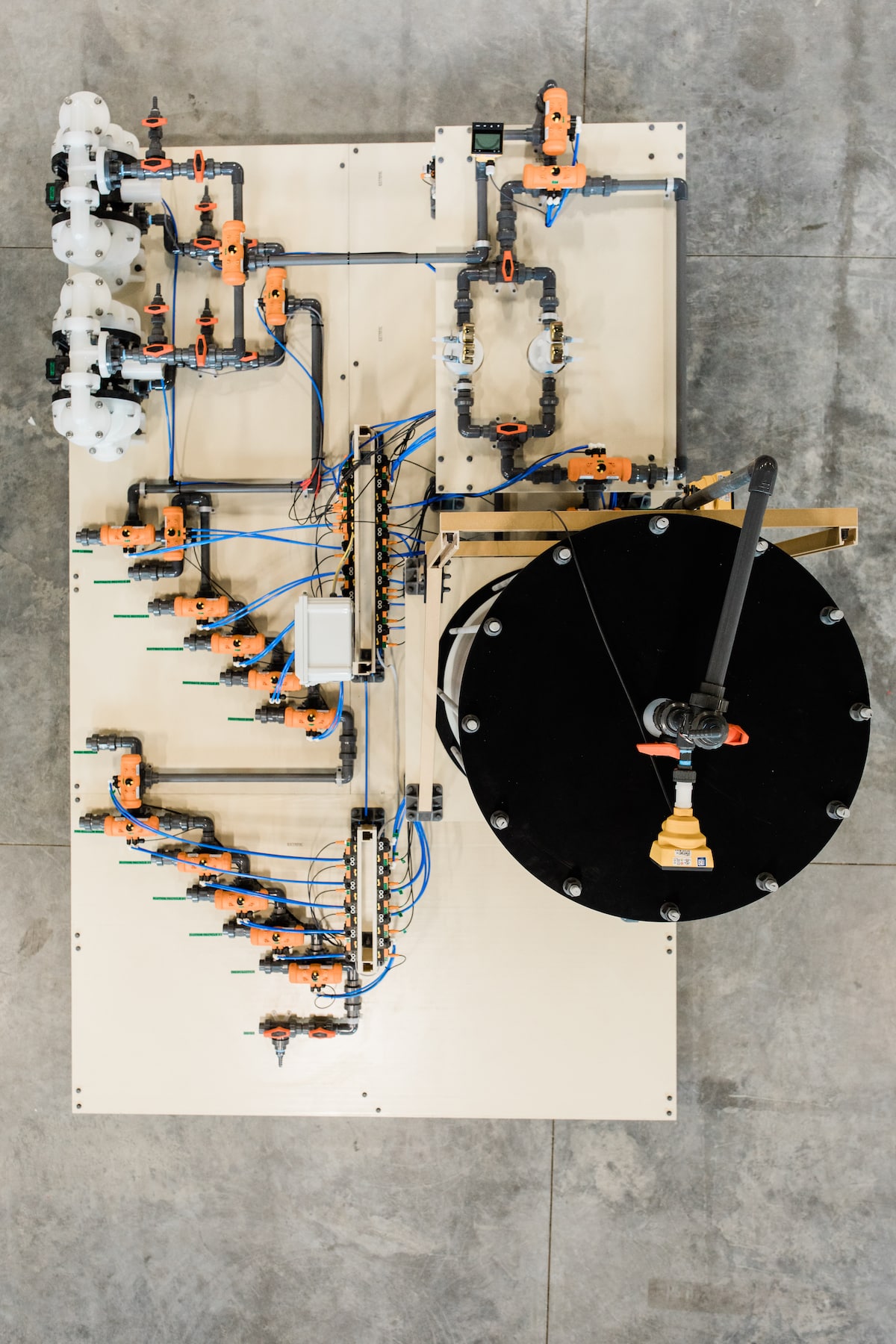

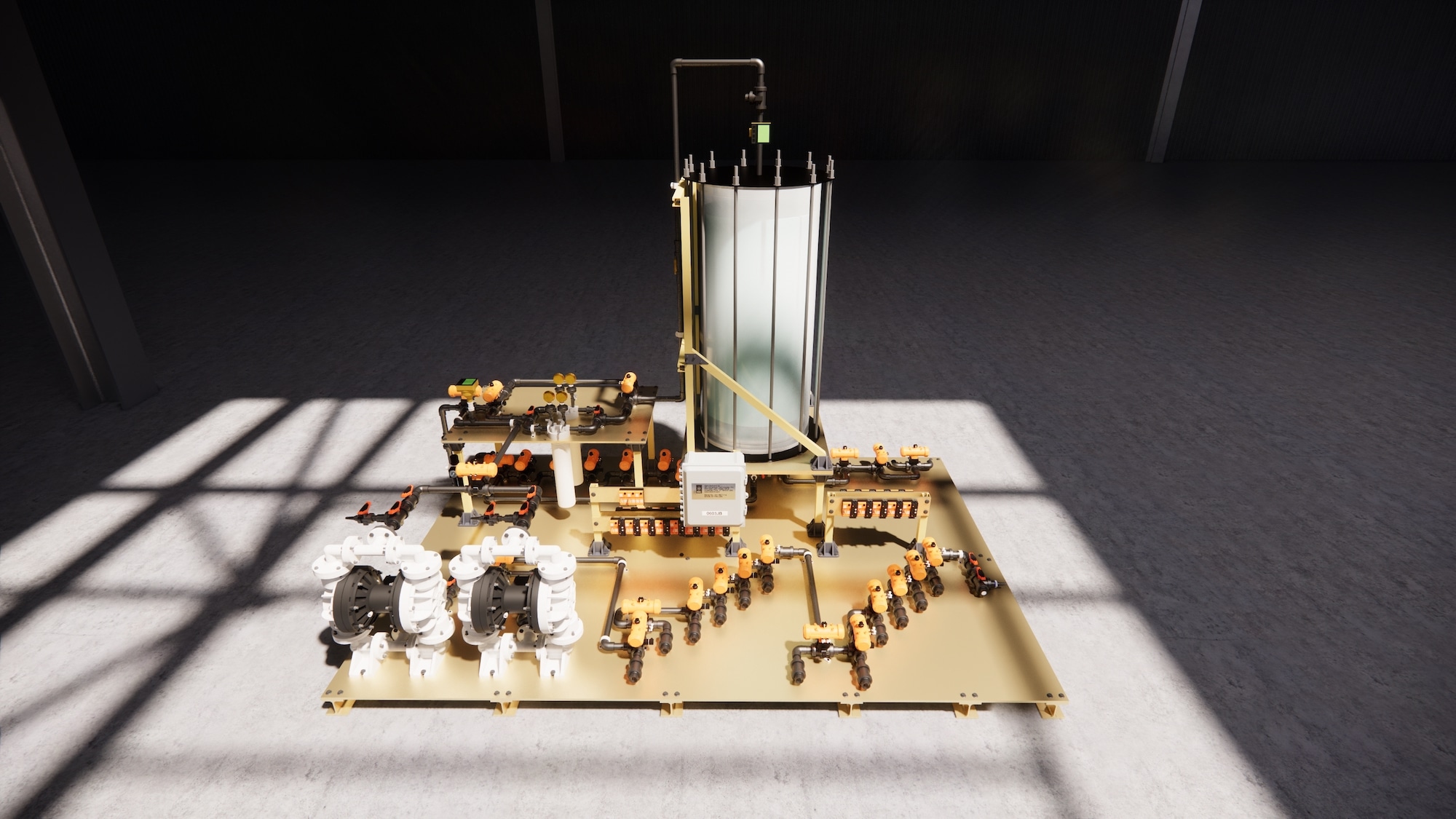

Industrial MRT™ separation systems incorporate SuperLig® solid phase particles (~0.5mm) such as silica gel or polymer substrates to which a ligand, highly selective for the target metal, has been covalently attached. The SuperLig® beads are packed into fixed-bed columns that are built in skid-mounted modular form, and are fully automated for continuous operation. The feed solution is passed through the column and the target species is removed selectively from the solution.

Applications

IBC’s SuperLig® products are used in a wide range of highly selective metal cation and anion separations from complex matrices and incorporated into engineered MRT™ systems.

SuperLig® MRT™ systems are:

- Cost-Effectively Manufactured by IBC to Meet Stringent Quality Standards

- Easy to Operate

- Economically Advantageous

- Proven to Provide Significant Improvements in Process Conditions

- Distinguished by High Selectivity

- Industrially Demonstrated to Meet Customer’s Needs and Deliver Exceptional Value

- Widely Applicable Across Industries

Cost-Effectively Manufactured by IBC to Meet Stringent Quality Standards

Economically Advantageous

Significant economic advantages result from the use of SuperLig® MRT™ systems. Here are the top four:

1st

High selectivity, high recovery rates, high loading capacity, and rapid loading and release kinetics of SuperLig® products result in Lower capital and operating costs in commercial-scale operations compared to other separation procedures due to high selectivity, high recovery rates, high loading capacity, and rapid loading and release kinetics of SuperLig® products.

2nd

Simple reagents compatible with the customer’s plant operation are used for washes and elutions. These reagents normally work effectively at ambient temperatures and pressures. The metal is completely eluted (removed or stripped) from the column in a small volume, resulting in a concentrated pure metal eluate. The elution process is rapid and amenable to automated on-line multi-cycle operation.

3rd

No organic solvents are used, thereby avoiding associated costs as well as negative environmental, safety and health effects.

4th

Very high first pass recovery rates maximize metal yields, minimize metal inventory (lock-up) in the processing pipeline, ensure that metal can be released promptly for sale and thereby greatly reduce metal financing costs (working capital).

Distinguished by High Selectivity

SuperLig® products are designed to bind selectively with ions based on multiple parameters such as size, coordination chemistry, donor atom type and number, and geometry. In contrast, separation methods used in conventional technologies such as ion exchange, solvent extraction and precipitation generally recognize differences between ions based only on a single parameter (e.g., charge, solubility, size).

High Selectivity of SuperLig® MRT™ Products

High individual metal selectivity of MRT™ systems allows very efficient load and elution profiles. The target ion is easily and completely released from the SuperLig® column and recovered as a high purity, concentrated product in a small volume of eluate that can be readily processed and sold at maximum value. Metal recovery rates are greatly improved and low metal concentrations in the feed are significantly upgraded in the eluate; reagents, time, labor, and space are conserved; and waste generation is minimized.

Low Selectivity of Conventional Technologies

In contrast to MRT™ processes, separation methods used in conventional technologies such as ion exchange, solvent extraction and precipitation generally recognize differences between ions based only on a single parameter (e.g., charge, solubility, size). Low selectivity results in poor recovery, low concentration factors, and impure products. Additional processing is required incurring substantial costs for additional space, chemicals, energy, equipment, labor and treatment of secondary waste production. Throughput time is increased thus requiring high in-process metal inventory (working capital.)

Highly Selective Compared to Ion Exchange (IX) and Solvent Extraction (SX)

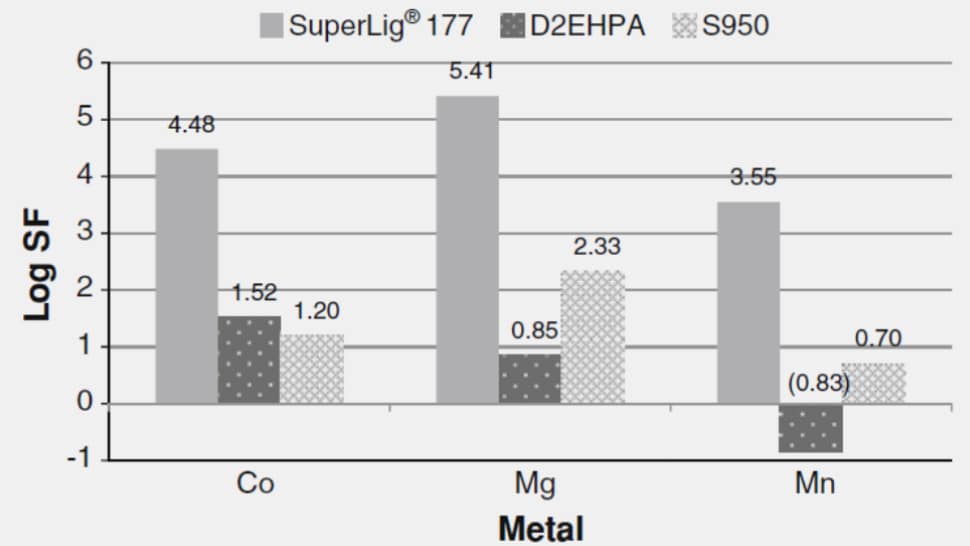

CASE STUDY: Purification of Cobalt

To meet strict battery-grade cobalt (Co) metal specifications, cadmium (Cd) must be removed to a very low level. A comparative Mintek (South Africa) study found SuperLig® 177 to be orders of magnitude more selective for cadmium removal from cobalt electrolyte compared to the solvent extraction agent di-2-ethylhexyl phosphoric acid (D2EHPA) or the adsorption agent amino-methyl phosphoric acid resin (Purolite S950):

- Cadmium concentration: 6 mg/L in a cobalt electrolyte solution containing 60 g/L cobalt along with magnesium, aluminum, silicon, calcium, manganese, iron, nickel, copper, zinc and lead

- SuperLig® 177 cadmium loading: 2.9 g/L cadmium

- Cadmium upgrading ratio: 480

- Cadmium eluate purity: contained nearly non-detectable amounts of cobalt and matrix elements

- The selectivity factor (SF) for cadmium over each of these elements was very large compared to solvent extraction and ion exchange (see Figure at right)

- Pure, recovered cadmium can be sold to help defray the costs of the separation

Plot of the log of the selectivity factor (log SF) vs metal for the separation by SuperLig® 177, D2EHPA and S950 of cadmium from cobalt, magnesium and manganese.

Source: Read our paper: Metal Separations and Recovery in the Mining Industry

Orders of Magnitude Higher Binding Constants than those of Ion Exchange (IX) and Chelating Ion Exchange Resins

Case Study: Removal, Separation and Recovery of Heavy Metals from Industrial Waste Streams

- Very high (>99%) first pass recovery rate of the target metal

- Greater flexibility in predesigning selective separation systems

- Higher loading capacities

- Rapid kinetics

- Greater ability to bind and recover metals from solutions containing low concentrations of the target metal

- Make multiple passes necessary to obtain high purity, versus single pass MRT™ systems

- Add new contaminants during the loading and elution processes, which require additional steps for proper recovery or disposal

- Cause separation effectiveness to decrease as target metal concentrations decrease, making recovery of metals from low-level feed solutions inefficient

- Are rate diffusion limited, with slow kinetics, making the amount of time the target metal is tied up in the process (i.e., the metal inventory time) very long compared with MRT™

- Require larger process space requirements, resulting from the low selectivities and long loading and elution times

- Make incorporation of IX processes online into flow sheets that have high flow rates difficult due to low selectivity, slow kinetics, and low binding constant values

| Metal Ion | SuperLig® | Regular IX, Sulfonic acid group | Chelating IX, Iminodiacetic acid group |

|---|---|---|---|

| Ni2+ | 17.0 | <0.7 | 4.9 |

| Cu2+ | 22.0 | <0.7 | 7.3 |

| Zn2+ | 14.4 | <0.7 | 3.8 |

| Cd2+ | 13.8 | <0.7 | 3.0 |

| Pb2+ | 14.4 | <0.7 | 4.2 |

| Ag+ | 13.8 | <0.7 | <0.7 |

Widely Applicable Across

Industries

Easy to Operate

SuperLig® products bind ions selectively even when the target ion is present in a highly acidic or basic solution and/or in solutions containing high concentrations of competing ions. This high selectivity reduces the number of process steps and makes SuperLig® MRT™ systems easy to operate.

High species selectivity, high binding factors, and rapid reaction kinetics result in very efficient separations. The simple elution chemistry features a wide choice of eluent formulations to ensure compatibility with customer plant requirements. Since small volumes of eluent are used, highly concentrated eluate solutions are produced from which pure products can easily be obtained.

The above procedure is illustrated below for the purification of copper electrolyte through the selective separation and recovery of bismuth as a highly pure saleable product from copper electrolyte.

Steps in the operation of the SuperLig® MRT™ process in the column mode:

| Step | Operation |

| Loading | The target metal is selectively extracted from the feed by the SuperLig® resin, which has previously been loaded into the column at high capacity. |

| Pre-elution wash | The remaining feed solution is washed from the column leaving only the target metal bound to the SuperLig® resin. |

| Elution | All of the bound metal is completely eluted from the column with a small amount of eluent forming an eluate solution containing the concentrated target metal. Bed volumes of 1-2 are typical in the elution step. |

| Post-elution wash | The remaining eluent solution is washed from the column and the cycle is repeated starting with the loading step. |

Proven to Provide Significant Improvements in Process Conditions

The exceptional selectivity of SuperLig® products for specific metals results in MRT™ separation systems that have high loading capacities for the metal of interest, thus negating further expensive and time-consuming separations required by conventional technologies. MRT™ systems can be designed and constructed for any size, concentration, and volume-throughput requirement.

Environmentally and Ecologically Friendly Process

SuperLig® products selectively and rapidly separate, concentrate and recover target metals in pure form with a minimal carbon footprint. Accompanying metals are retained for value or disposed of in an environmentally friendly manner. The resulting stream, devoid of its metal content, can be safely discharged. Separation and recovery of valuable, toxic and other metals in pure form at or near their source from mining, industrial processes, spent secondary waste and other streams for re-use or safe disposal are of enormous value from environmental, ecological, and sustainability standpoints.

Short Process Time

Time is a major concern in many industries that involve the recovery of metals from process solutions, recycled material and wastes. MRT™ processes offer significant time advantages for the following reasons:

1st

Metal loading times are rapid.

2nd

Rapid loading times combined with rapid and complete elution of the target metal from the column producing a small volume of eluate results in turnaround times for consecutive runs that are very fast compared to those of conventional technologies. MRT™ systems rapidly process material, thereby minimizing metal lock-up and releasing metal earlier for sale.

3rd

Markedly shortened processing times and increased productivity result from the incorporation of MRT™ systems into existing flow sheets of commercial operations.

Small Floor Space Requirement

MRT™ systems are compact making their use appealing to companies where space is at a premium. This factor makes the use of MRT™ processes feasible for on-site separation, recovery, and purification of target metals eliminating the necessity of finding off-site locations for waste disposal of unwanted metal impurities.

Industrially Demonstrated to Deliver Exceptional Customer Value

SuperLig® MRT™ systems can provide superior economic and operational advantages and achieve positive Environmental, Social and Governance (ESG) impact.- Rapidly process material, thereby minimizing metal lock-up and release of metal earlier for sale

- Do not introduce or produce new pollutant(s)

- Do not exchange one contaminant for another

- Are environmentally friendly, operate at ambient pressures and temperatures, and have minimal carbon footprint

- Can be used as efficiently with large as well as very small volumes of solution

- Are highly selective for the targeted metal(s) even in highly acidic, highly basic, or concentrated salt solutions

- Are highly selective for a targeted metal even when other similar metals are present at much greater concentrations

- Maintain efficiency even as the metal concentration decreases with respect to high concentrations of matrix ions

- Can be used to concentrate a separated metal to a very large degree

- Can be automated and incorporated into a real time procedure for the continuous separation of a metal from a solution and recovery of the metal in a highly purified form in a concentrated solution